The Ultimate Guide to Fillet Weld High Quality Control: Guaranteeing Strength and Durability in Your Welded Joints

In the realm of welding, making sure the strength and sturdiness of fillet welds is paramount for the stability of bonded joints. As we embark on this exploration of fillet weld high quality control, we will certainly uncover necessary variables that influence weld stamina, dive right into effective evaluation techniques, and review strategies for stopping usual weld issues.

Importance of Fillet Weld Quality Assurance

Making sure correct fillet weld quality assurance is critical in guaranteeing the structural integrity and longevity of welded elements in different markets. Fillet welds are frequently utilized in architectural steelwork, bridges, stress vessels, pipes, and various other important framework where the toughness of the weld is critical to total safety and security and efficiency. Quality assurance actions such as aesthetic examinations, non-destructive screening, and adherence to welding treatments assist determine potential defects like lack of blend, insufficient infiltration, undercutting, or excessive support.

Trick Variables Impacting Weld Strength

Attaining optimal weld stamina requires mindful factor to consider of various crucial variables that influence the integrity and toughness of the welded joint. The very first essential variable appertains joint prep work, which involves cleaning up the base steels to remove any type of impurities that could compromise the weld. In addition, the fit-up of the joint is necessary to make certain proper penetration and combination of the filler product.

The selection of the suitable welding method and criteria also plays a considerable function in establishing weld strength. Elements such as warm input, traveling rate, and electrode angle can influence the top quality of the weld. Keeping the correct interpass temperature during multi-pass welding is vital to prevent breaking and guarantee a strong bond between the layers.

Furthermore, the choice of filler product and its compatibility with the base steels is critical for attaining high weld toughness. Making use of filler product with the proper mechanical buildings can boost the general stability of the weld. Lastly, post-weld heat therapy and correct assessment methods are important steps in ensuring the toughness and toughness of the welded joint.

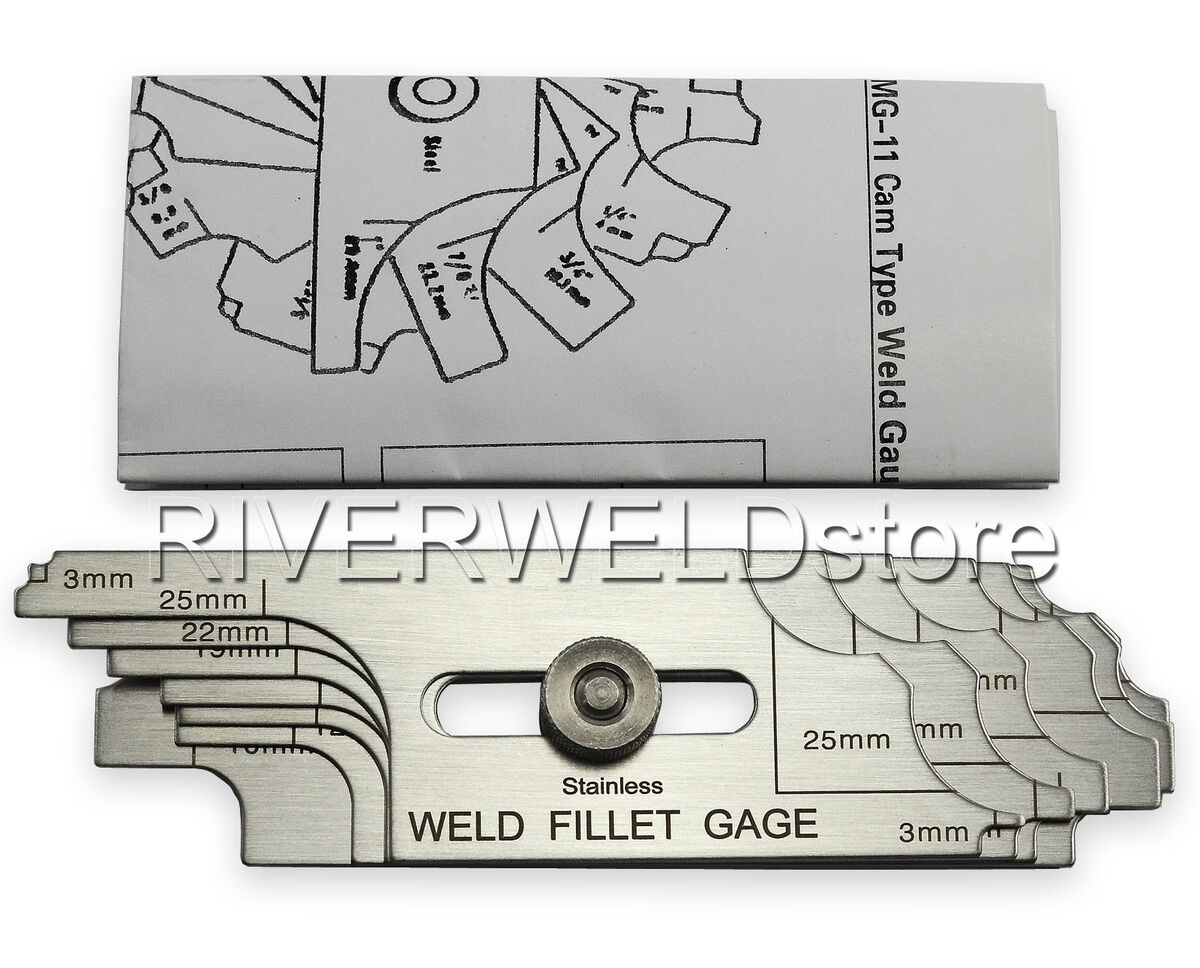

Examination Techniques for Weld Integrity

An additional important inspection technique is fluid penetrant testing, where a fluid dye is related to the weld surface - Gauge Fillet Weld. The dye seeps right into any surface-breaking issues, making them visible under UV light. This technique works for finding flaws that might not be noticeable to the naked eye

Ultrasonic testing is also commonly used for inspecting weld integrity. High-frequency acoustic wave are routed into internet the weld, and any kind of disturbances in the audio wave pattern indicate prospective defects like splits or lack of fusion.

These evaluation techniques play a crucial duty in making certain the quality and reliability of welds, eventually adding to the overall strength and resilience of welded joints in industrial setups.

Stopping Common Weld Issues

In order to keep the structural integrity of welded joints in industrial applications, it is crucial to execute preventative procedures to resolve common weld problems. One typical flaw is absence of blend, where the filler material fails to bond sufficiently with the base steels, bring about weak points in the weld. This can be prevented by guaranteeing proper warm control and utilizing the appropriate welding method.

One more regular issue is porosity, triggered by gas entrapment in the weld metal during the welding process. To stop this, it read this is necessary to clean the base steels extensively, make use of completely dry electrodes, and preserve an appropriate welding environment with proper air flow.

In addition, fractures in welds can jeopardize the joint's strength. To avoid this issue, it is vital to manage the cooling rate after welding, make use of pre-heating when required, and select ideal welding criteria.

Enhancing Weld Sturdiness With Proper Strategies

One vital method to improve weld longevity is to guarantee correct weld grain placement. By positioning the weld grain properly within the joint, the weld's strength and resistance to tiredness can be dramatically improved.

Selecting the appropriate filler steel and making sure the sanitation of the base metals can prevent inclusions and other defects that could endanger the weld's durability. By implementing these correct methods, welders can guarantee that their welded joints exhibit exceptional stamina and toughness, meeting the highest high quality standards.

Verdict

Finally, maintaining excellent quality control criteria for fillet welds is vital for making certain the stamina and durability of welded joints. By understanding the crucial factors impacting weld strength, using inspection techniques for weld honesty, avoiding usual weld problems, and using proper methods, welders can boost the overall sturdiness of their welds. It is important to focus on quality control steps to create reliable and resilient welded joints.

In the world of welding, making certain the strength and sturdiness of fillet welds is vital for the honesty of welded joints. As we begin on this expedition of fillet weld top quality control, we will uncover vital aspects that affect weld toughness, dive right into reliable inspection methods, and discuss techniques for avoiding typical weld flaws.Accomplishing ideal weld stamina needs cautious consideration of various essential elements that influence the integrity and durability of the welded joint (Gauge Fillet Weld).In verdict, keeping high top quality control requirements for fillet welds is why not find out more vital for making sure the stamina and sturdiness of welded joints. By understanding the vital variables impacting weld stamina, utilizing inspection approaches for weld stability, avoiding common weld issues, and utilizing proper strategies, welders can improve the overall durability of their welds